Welcome to Our Comapny

Call Me - 08071930556

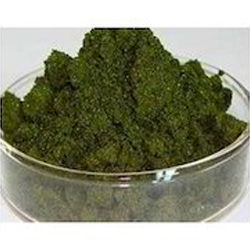

Direct Blue Dyes

Product Details:

- Appearance Bright Blue Powder

- Odour Odourless

- Ph Level 6.0 - 8.0 (1% solution)

- Storage Instructions Store in a cool, dry place, away from direct sunlight

- Density 0.70 Gram per cubic centimeter(g/cm3)

- Molecular Weight 992.82 g/mol

- Solubility Soluble in water

- Click to View more

X

Direct Blue Dyes Product Specifications

- Odourless

- 6.0 - 8.0 (1% solution)

- Soluble in water

- 992.82 g/mol

- Store in a cool, dry place, away from direct sunlight

- Direct Dyes

- Textile, Paper, Leather, Silk, Wool

- Powder

- Dyeing, Printing, Padding

- Synthetic Organic Dye

- Direct Blue, Direct Blue 86

- Depends on process; typically 1-2 hours

- 0.70 Gram per cubic centimeter(g/cm3)

- Aromatic amines, Naphthalene derivatives

- 24 Months

- Direct Blue Dyes

- 24 months from date of manufacture

- Bright Blue Powder

- Industrial dyeing process

- 98%

- 1330-38-7

Direct Blue Dyes Trade Information

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

We are acknowledged in providing a unique range of Direct Blue Dyes. These are used to dye cotton materials. These dyes are a substantive dye for textiles with high contents of cellulose. These dyes are suitable to tint cinematographic film. Direct Blue Dyes are resistant to fading and highly conjugated molecular structures. These dyes are mainly utilized in paper industry. These contain no harmful and artificial chemicals. These are an organic compound which contain a high content of cellulose.

Application Versatility

Direct Blue Dyes are designed for a wide range of applications such as dyeing, printing, and padding. Their strong affinity for cellulose fibers allows for brilliant color results on textiles, paper, leather, silk, and wool, accommodating various industrial processes with dependable performance and vibrant shades.

Sustainability and Safety

These dyes are biodegradable with a low heavy metal content, minimizing environmental impact during disposal. Their non-toxic nature under recommended usage conditions assures safe handling for workers and end-users, aligning with modern environmental and safety standards for industrial chemicals.

Product Features and Packaging

Offered in bright blue powder form, Direct Blue Dyes are odorless, water-soluble, and supplied in secure 25 kg HDPE bags with inner liners for protection. The recommended storage is in cool, dry spaces away from sunlight, ensuring the dye's efficacy and longevity for up to 24 months.

FAQ's of Direct Blue Dyes:

Q: How are Direct Blue Dyes applied to different materials?

A: Direct Blue Dyes can be used through dyeing, printing, and padding methods. These processes allow the dye to deliver strong, vibrant blue shades on textiles, paper, leather, silk, and wool, thanks to its excellent affinity for cellulose and protein fibers.Q: What benefits do Direct Blue Dyes offer in industrial dyeing?

A: Direct Blue Dyes provide intense color strength, high staining efficiency, good washing fastness, and moderate to good light fastness, ensuring vibrant, durable results. They are easy to dissolve in water, making them convenient to use with various textile auxiliaries during manufacturing.Q: When should Direct Blue Dyes be used for optimal results?

A: For best performance, Direct Blue Dyes should be used within 24 months from the date of manufacture and stored in a cool, dry place away from sunlight. Adhering to the recommended usage and suitable application methods maximizes color longevity and consistency.Q: Where is the ideal storage for Direct Blue Dyes?

A: Direct Blue Dyes should be stored in a cool, dry location, protected from direct sunlight to maintain their stability and quality. The packaging in HDPE bags with an inner liner further shields the powder from moisture and contamination.Q: What is the environmental impact of Direct Blue Dyes?

A: Direct Blue Dyes are biodegradable and have low heavy metal content, which contributes to reduced environmental risk during disposal and processing. They meet sustainability requirements for modern textile and industrial dyeing operations.Q: How compatible are Direct Blue Dyes with textile auxiliaries?

A: These dyes possess excellent compatibility with a range of textile auxiliaries, enhancing processing efficiency and ensuring uniform, high-quality results in dyeing and printing applications.Q: What precautions should be taken during usage?

A: Although Direct Blue Dyes are non-toxic under recommended conditions, it is best to use protective gear and follow industry protocols. Ensure proper ventilation, avoid direct skin contact, and keep the product stored securely according to the provided instructions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese